FlowWeb OPC Controller

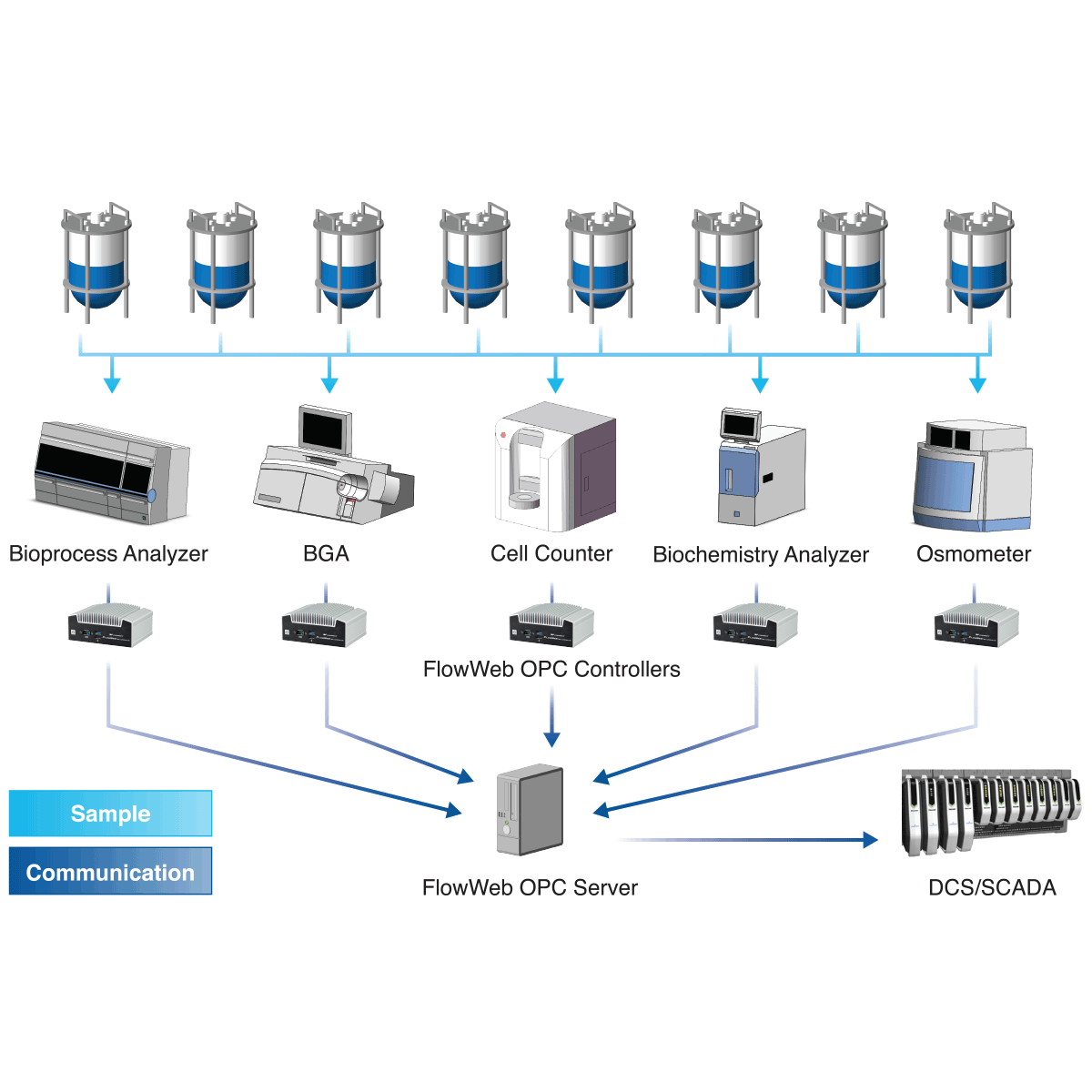

Whether networking a single bioreactor system, an entire PD lab, or multiple labs/suites, the FlowWeb™ OPC Controller provides a simple solution for improving bioprocess technology and control by expanding PAT options and enhancing existing DCS/SCADA system functionality.

The FlowWeb™ OPC Controller provides innovative data management and a comprehensive, integrated PAT strategy for effective bioprocess management. The controller works with any OPC-enabled process management system. It seamlessly acquires and integrates data from multiple on-line, at-line, and off-line analytical instruments and exports to any OPC-enabled DCS/SCADA system or data historian. OPC communication is web-based and can be established across any network. No additional servers are required. Some external devices can be remotely controlled.

- Description

- Product Specifications

- Features of the FlowWeb™ Controller

- FlowWeb™ Controller Interfaces

- Features of the FlowWeb™ Server

- Literature

Description

FlowWeb™ OPC Server Product Description

FlowWeb™ OPC Controller requires FlowWeb™ OPC Server Software, a software application that responds to requests and provides data to one or more OPC clients. This connects to the hardware and sends commands to or receives data from the hardware. OPC-enabled systems are implemented in server/client pairs, with one application acting as an OPC client and another as an OPC server. When in an OPC-enabled system, where neither application is an OPC client and both are OPC servers, a thin client (bridge) OPC client is used to connect both OPC servers. The “thin client” requests data from one server and immediately sends it to the other OPC server.

Product Specifications

| Windows PC Hardware Required | Ethernet connectivity |

|---|---|

| Windows OS Supported | Windows 2000 |

Features of the FlowWeb™ Controller

- Simultaneous on-line monitoring of up to 20 analytical devices (1 device/OPC Controller) via the OPC server

- Exports analytical data into any OPC-enabled DCS/SCADA system or data historian

- Facilitates real-time process monitoring and control and implementation of PAT initiatives

- Enables the conversion of data into information

- Highly flexible system with multiple communication options and interfaces

- Supports OPC Data Access (DA & UA)

- Uses web-based software for smooth integration into existing lab network and SCADA

- Remote access using IP address and web browser

- No annual license fees

FlowWeb™ Controller Interfaces

- Advanced Instruments (AI) Osmometers

- Beckman Coulter Vi-CELL XR Cell Viability Analyzer

- Roche Cedex Bio HT Bioprocess Analyzer

- Siemens RAPIDLab 1200 Blood Gas Analyzers (BGA)

- All YSI® Biochemistry Analyzers

Features of the FlowWeb™ Server

- Easy configuration

- Supports tag browsing

- Fully compliant OPC DA (Data Access) 1.0 and 2.0

- Permits read and write access to available data points

- Performs extensive error tracking and management

- The software is 21 CFR, part 11 compliant

Literature

FlowWeb™ Brochure

Flownamics® has been creating innovative, high quality solutions for the biotechnology and bioprocess industry for over 27 years.

Our products provide our customers with the tools that they need to improve their processes through automation. This results in higher quality data, more time, and a better work/life balance by requiring less off shift and weekend workloads. Contact Flownamics® to see how our products can make a difference for your process.

Our products have been featured in a variety of industry publications. Please visit our publications page to learn more.