Automated Sampling Systems

Future-proof your processes.

Increasing reliance on data analytics for robust process control and scalability calls for automated sampling to replace manual sampling in the bioprocess workflow.

Automated sampling reduces time, volume and dilution variability typically found in manual procedures. It reduces errors as fluid is drawn at a set time and is immediately capable of being stored at temperature to arrest biological activity, or sent directly to the prescripted analytical device as needed.

Description

Automated sampling systems play a critical role in the strategy to predict timed-process events, critical quality attributes (CQAs) and key performance indicators (KPIs) to ensure stability and predictability throughout the CMC process.

Flownamics has been solely focused on process fluid handling for over 29 years and provides unique patented technology to support time-critical events, sample size, and dilution rate. Being agnostic to variability of cell type and analytical device, it is the preferred choice in the bioprocessing industry.

Regardless of the application or need, we provide devices for either 1:1 bioreactor sampling or multiplexing and can equip the workflow with a turnkey solution for end-to-end fluid handling.

Seg-Flow® S₃ Automated Sampling Systems

The Flownamics Seg-Flow S3 product line is characterized by robust hardware, the intuitive handling of tubing with intelligent pinch valves and non-contact ultrasonic sensors. A series of LED status lights indicate the phases of sampling and the sequence of cleaning.

Seg-Flow® S3G Autosampling Systems

The Flownamics Seg-Flow S3G is primarily used for on-line pH and gas analysis when interfaced with an analyzer with BGA functionality. The system is also able to connect to other analyzers such as biochemistry analyzers, cell analyzers, HLPC systems and our Raman IM Module.

Seg-Flow® PS Sampling System

Patent Pending

Low shear makes the Flownamics Seg-Flow PS ideally suited for applications in both Cell and Gene Therapy. Optimized for both Upstream and Downstream processes. Standalone or multiplex up to 16 modules.

Acquire Automated Sampler with Fraction Collector

Flownamics developed the Acquire to handle automated sampling applications that only require fraction collection.

The Acquire is a compact, economical autosampler that can send cell-free or cell-containing samples from up to 8 reactors/process streams to various sized well plates & vials. The system can be used in cell-culture, fermentation and purification applications.

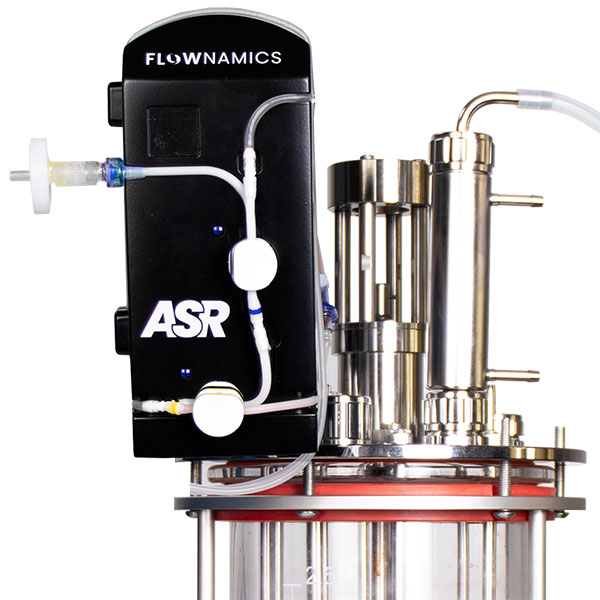

Automated Sampling Regulator

Aseptic Sampling Regulator (ASR)

An Aseptic Sampling Regulator (ASR) is installed at each reactor or process stream that is connected to a Seg-Flow S3, a Seg-Flow S3G and an Acquire Automated Sampling System. (The Seg-Flow PS Sampling System does not require an ASR.) The ASR manages the sampling and cleaning of the line between the reactor and the Seg-Flow.

ASR+ Aseptic Sample Regulator

ASR+ serves the same function as the ASR. However, it enhances the capabilities of a Seg-Flow S3, a Seg-Flow S3G and the Acquire by withdrawing both a cell-free and cell-containing sample from a single line.

Flownamics® has been creating innovative, high quality solutions for the biotechnology and bioprocess industry for over 27 years.

Our products provide our users with the tools that they need to improve their processes through automation. This results in higher quality data, more time, and a better work/life balance by requiring less off shift and weekend workloads. Contact Flownamics® to see how our products can make a difference for your process.

Our products have been featured in a variety of industry publications. Please visit our Publications page to learn more.