Sampling from TFF and ATF Systems

Automated, Real-Time Sampling from TFF and ATF Harvest Lines

Discover the benefits of automated, cell-free sampling from TFF and ATF systems—improving data reliability, process control, and downstream efficiency.

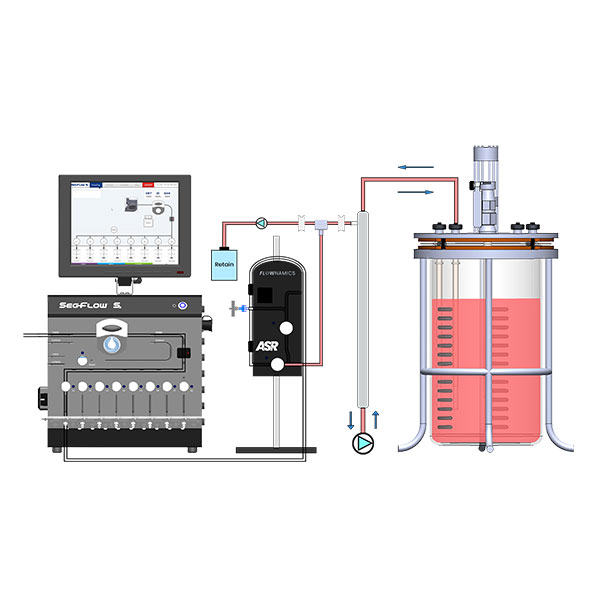

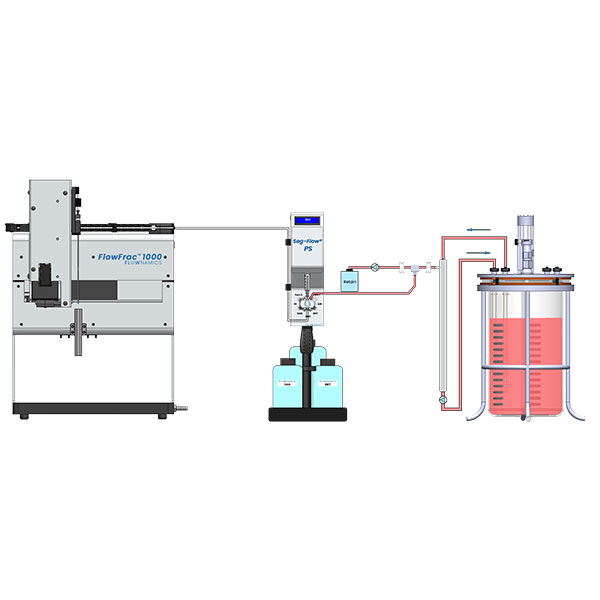

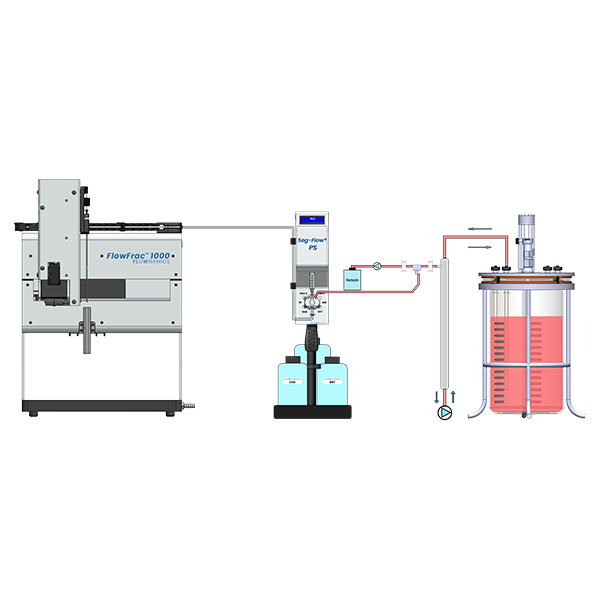

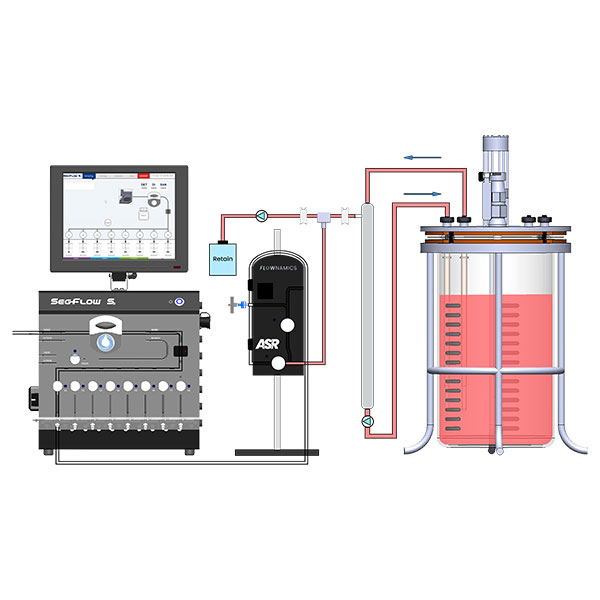

Related products: FlowFrac™ 1000, Seg-Flow® PS, ASR

- Description

- Product Specifications

- The Advantages of TFF/ATF Retentate Line Direct Sampling

- Product Highlights

Description

Obtaining a cell-free sample from a tangential flow filtration (TFF) or alternating tangential flow (ATF) harvest line offers numerous advantages for bioprocessing efficiency and control.

By enabling real-time process monitoring and control, automated sampling ensures accurate measurement of key process parameters like titer, metabolites, and nutrients—without disrupting operations. The risk of contamination is minimized through direct, sterile sampling, eliminating manual errors and exposure to environmental contaminants.

This approach also improves sample consistency and quality, providing truly representative, cell-free samples that enhance data reliability. Additionally, automated sampling increases efficiency by reducing the need for centrifugation or filtration, streamlining downstream processing (DSP) and minimizing product loss.

Seamless integration with process analytical technology (PAT) and OPC software enables automated data transfer and process control, allowing for real-time insights and optimization. By enhancing process analytics and automation, this system supports advanced PAT tools—ensuring better yields, reduced deviations, and improved scalability in bioprocessing.

Flownamics® has been creating innovative, high quality solutions for the biotechnology and bioprocess industry for over 27 years.

Our products provide our users with the tools that they need to improve their processes through automation. This results in higher quality data, more time, and a better work/life balance by requiring less off shift and weekend workloads. Contact Flownamics® to see how our products can make a difference for your process.

Our products have been featured in a variety of industry publications. Please visit our Publications page to learn more.